Vibration Analysis Alberta

Operating out of Alberta, Canada, DVA represents a consulting engineering firm that excels in providing top-tier quality and services in the vibration analysis of rotating machinery. The acronym DVA stands for Displacement, Velocity, and Acceleration, underscoring our specialized focus. With the capability to tackle and effectively solve a diverse range of vibration issues, our expertise spans across various industries, catering to all forms of rotating equipment.

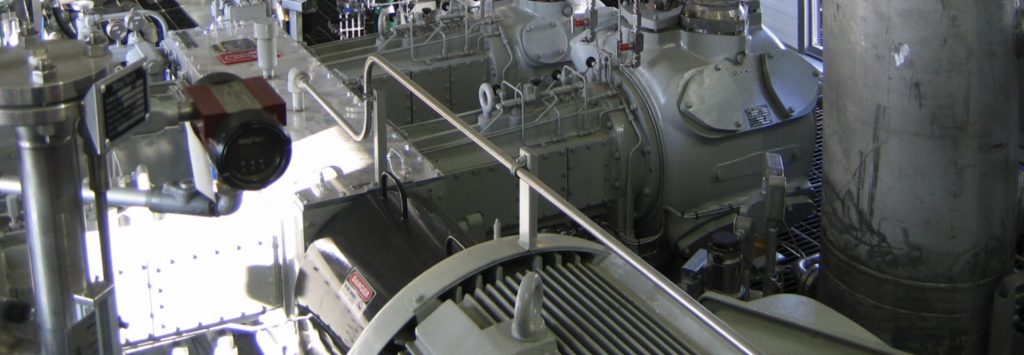

Dynamic Field Balancing in Alberta

In industries where the performance of rotating machinery plays a critical role, such as aerospace, manufacturing, and power generation, the emphasis on achieving and maintaining peak operational efficiency cannot be overstated. These sectors depend heavily on the reliability and effectiveness of their machinery to meet production goals, ensure safety, and minimize downtime. In this context, one of the paramount concerns is the management and reduction of vibration levels within the machinery. High vibration is not only a precursor to potential failures but also a significant factor in energy inefficiency and increased wear and tear on components, leading to premature equipment degradation.

To combat these challenges, a fundamental strategy employed is the maintenance of low vibration levels, which is instrumental in enhancing the efficiency and longevity of machinery. Achieving this often involves a precise and technical process known as trim balancing. Trim balancing is an intricate procedure that involves making fine adjustments to the mass distribution of rotating components within machinery. The goal is to ensure that the center of mass is aligned with the axis of rotation, thereby minimizing vibration and promoting smoother operation.

This process, while conceptually simple, requires a high degree of precision and expertise. It often involves the use of sophisticated balancing equipment and techniques, such as vibration analysis and dynamic balancing, to accurately identify imbalances and determine the precise corrective actions needed. The adjustments made can range from adding or removing small weights, repositioning components, or even altering the shape of components to achieve the desired balance.

The true value and effectiveness of trim balancing, however, go beyond the technicalities of the process itself. It is heavily reliant on the skill, experience, and insights of seasoned technicians and engineers who are adept at diagnosing complex vibration issues and implementing the most effective solutions. These professionals bring a wealth of knowledge and practical experience, enabling them to not only execute the technical aspects of trim balancing but also to anticipate potential challenges and adapt their strategies accordingly.

Moreover, in an era where machinery and equipment are becoming increasingly complex and sophisticated, the role of trim balancing assessment and the expertise of these technicians become even more critical. They ensure not only the optimal performance of machinery but also contribute to the overall reliability and efficiency of operations in sectors where the stakes are high, and the margins for error are slim. In conclusion, while trim balancing might appear to be a straightforward task, its significance in the context of rotating machinery performance is profound, underpinned by the unparalleled skills of dedicated professionals.

Rotating Equipment Vibration Analysis in Alberta

DVA Industrial Solutions – Vibration Analysis Alberta, is revolutionizing the field of Rotating Equipment Vibration Analysis in Alberta, setting a new standard for precision in the evaluation of machinery health. Our state-of-the-art approach goes beyond the surface, delving into the heart of machinery to examine bearings, shafts, and other critical components with an unprecedented level of detail. By harnessing the latest in vibration signal technology, we are able to dissect and interpret complex vibration patterns with extraordinary accuracy. Our comprehensive analysis covers speed, amplitude, frequencies, and harmonics, providing you with a deep understanding of your machinery’s condition. Through our extensive resources, including insightful real-world case studies and in-depth technical articles, we equip you with the knowledge to effectively identify and tackle issues. Whether you’re concerned about bearing positions, shaft integrity, or rotor dynamics, our advanced methodologies ensure you have the insights needed to maintain a safe and efficient working environment.

Expanding our reach and fostering community engagement, DVA Industrial Solutions – Vibration Analysis Alberta has established a vibrant presence on LinkedIn, where industry professionals gather to share knowledge and experiences. This platform allows us to connect with our audience on a personal level, encouraging the exchange of ideas and best practices. Additionally, we prioritize your digital experience and privacy, as evidenced by our comprehensive cookie policy. Our commitment to transcending linguistic barriers is reflected in our multilingual content offerings, making our world-class resources accessible to a global audience. Our product line is thoughtfully designed to address a wide range of factors that influence the health of rotating equipment, ensuring that your needs are fully met. Join us on your journey to reliability; with DVA Industrial Solutions, you’re choosing a partner dedicated to precision, safety, and excellence, ensuring your utmost satisfaction in every interaction.

Our Other Services

LASER ALIGNMENT ALBERTA

The benefits of precision shaft alignment are clear: machines consume less power; operate with appropriate vibration levels; and there is limited wear on bearings, couplings and mechanical seals thereby extending equipment life.

MODAL ANALYSIS AND OPERATING DEFLECTION SHAPE ALBERTA

In the process of diagnosing rotating machinery, it is unavoidable to do some structural vibration analysis as well. Most often this is done by performing ODS (Operating Deflection Shape) Analysis or Modal Analysis.

PREDICTIVE MAINTENANCE (PDM) SERVICES ALBERTA

DVA’s Predictive Maintenance Programs and Services are an integral part of creating a healthy, reliable equipment operating environment. DVA’s services help to improve reliability, increase safety, optimize asset life, and enhance production and operating efficiencies.

INDIVIDUAL TRAINING PROGRAMS ALBERTA

DVA experts can provide your team with hands –on comprehensive training on instruments you use or any reliability/maintenance programs you want to implement and operate.

FAQ - Vibration Analysis

What does Vibration Analysis entail in Alberta?

Alberta, vibration analysis diagnostics involves the use of sensors and monitoring technologies to assess the vibrations emanating from industrial machinery and equipment. This diagnostic approach allows for the precise measurement and analysis of vibrational data, aiding in the early detection of faults such as imbalances, misalignments, and wear. By identifying these issues promptly, it helps avert expensive repairs and operational downtime.

Why is minimizing vibrations pivotal in the functioning of rotating machinery?

Keeping vibration levels low in rotating machinery is vital for maintaining operational efficiency and preventing premature wear and potential breakdowns. Dynamic Field Balancing plays a key role here, by meticulously adjusting the rotating parts to minimize vibrations, thereby enhancing the machinery’s performance and longevity.

How does Calibration influence Dynamic Field Balancing?

Calibration is fundamental to Dynamic Field Balancing as it guarantees the accuracy and reliability of the sensors and measurement devices involved in the process. Through precise calibration, the data collected during the balancing process is ensured to be accurate, thereby improving the fault detection and correction capabilities of the procedure.