Vibration Analysis Calgary

At DVA Industrial Solutions Inc., our vibration analysis services in Calgary ensure the reliability of your machinery. Our experienced technicians use advanced sensors and diagnostics to monitor equipment vibrations and assess their condition. We provide accurate data on amplitude, frequency, and velocity, helping you maintain optimal performance. By using cutting-edge software, we offer precise measurements and detailed reports. Our comprehensive analysis identifies potential issues before they become major problems, ensuring safety and reliability. We conduct regular monitoring to detect any changes in equipment behavior. Our team performs on-site assessments for immediate feedback and recommendations. Trust us for top-notch vibration analysis services in Calgary, AB, and keep your machinery running smoothly. Our expertise extends to various industries, including manufacturing, energy, and transportation, making us a versatile partner in maintenance and reliability.

Dynamic Field Balancing in Calgary

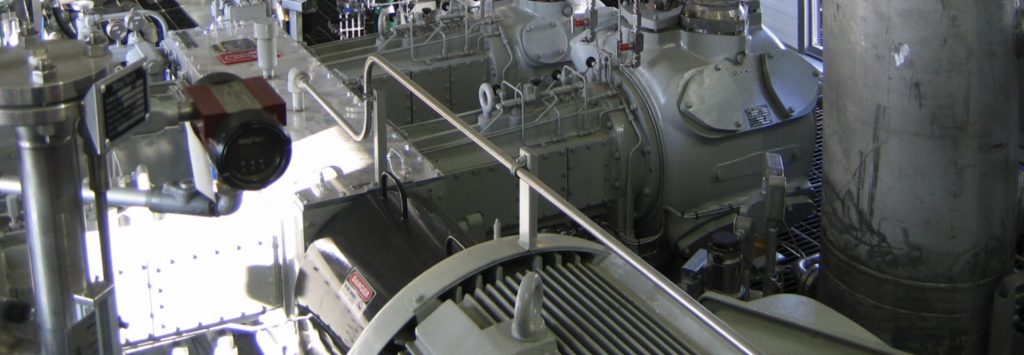

Rotating Equipment Vibration Analysis in Calgary

DVA Industrial Solutions Inc. specializes in rotating equipment vibration analysis in Calgary. Our skilled technicians use advanced sensors and analysis techniques to monitor and diagnose your machinery’s condition. We provide comprehensive data on vibration spectra, helping you identify and address issues promptly. Our services ensure your equipment’s reliability and extend its lifespan. With our detailed reports, you can make informed maintenance decisions. We cater to diverse industries, including power, oil, and gas, offering top-notch vibration analysis solutions. Furthermore, our team stays updated with the latest technologies and methodologies. We perform in-depth assessments to identify underlying causes of vibration issues. Choose us for expert rotating equipment vibration analysis in Calgary, AB, and ensure optimal performance and safety. Our services include training your staff to recognize and address potential vibration problems, enhancing your in-house capabilities.

Our Other Services

LASER ALIGNMENT ALBERTA

The benefits of precision shaft alignment are clear: machines consume less power; operate with appropriate vibration levels; and there is limited wear on bearings, couplings and mechanical seals thereby extending equipment life.

MODAL ANALYSIS AND OPERATING DEFLECTION SHAPE ALBERTA

In the process of diagnosing rotating machinery, it is unavoidable to do some structural vibration analysis as well. Most often this is done by performing ODS (Operating Deflection Shape) Analysis or Modal Analysis.

PREDICTIVE MAINTENANCE (PDM) SERVICES ALBERTA

DVA’s Predictive Maintenance Programs and Services are an integral part of creating a healthy, reliable equipment operating environment. DVA’s services help to improve reliability, increase safety, optimize asset life, and enhance production and operating efficiencies.

INDIVIDUAL TRAINING PROGRAMS ALBERTA

DVA experts can provide your team with hands –on comprehensive training on instruments you use or any reliability/maintenance programs you want to implement and operate.

FAQ - Vibration Analysis

What does Vibration Analysis entail in Alberta?

Alberta, vibration analysis diagnostics involves the use of sensors and monitoring technologies to assess the vibrations emanating from industrial machinery and equipment. This diagnostic approach allows for the precise measurement and analysis of vibrational data, aiding in the early detection of faults such as imbalances, misalignments, and wear. By identifying these issues promptly, it helps avert expensive repairs and operational downtime.

Why is minimizing vibrations pivotal in the functioning of rotating machinery?

Keeping vibration levels low in rotating machinery is vital for maintaining operational efficiency and preventing premature wear and potential breakdowns. Dynamic Field Balancing plays a key role here, by meticulously adjusting the rotating parts to minimize vibrations, thereby enhancing the machinery’s performance and longevity.

How does Calibration influence Dynamic Field Balancing?

Calibration is fundamental to Dynamic Field Balancing as it guarantees the accuracy and reliability of the sensors and measurement devices involved in the process. Through precise calibration, the data collected during the balancing process is ensured to be accurate, thereby improving the fault detection and correction capabilities of the procedure.