Vibration Analysis Regina

At DVA Industrial Solutions Inc., we specialize in providing top-notch vibration analysis services in Regina. Our skilled technicians use advanced sensors and diagnostic tools to monitor and evaluate the condition of your machinery. We deliver precise data on amplitude, frequency, and velocity to ensure optimal performance. With state-of-the-art software, we offer detailed measurements and comprehensive reports. Our thorough analysis helps identify potential issues before they escalate, ensuring safety and reliability. Regular monitoring detects any changes in equipment behavior, and our team conducts on-site assessments for immediate feedback and recommendations. Trust DVA Industrial Solutions Inc. for reliable vibration analysis services in Regina, SK, to keep your machinery operating smoothly. We serve various industries, including manufacturing, energy, and transportation, making us a versatile partner in maintenance and reliability.

Dynamic Field Balancing in Regina

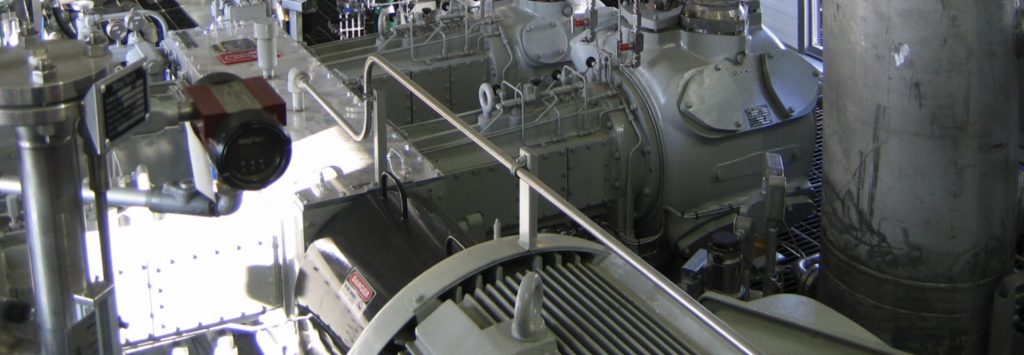

Rotating Equipment Vibration Analysis in Regina

DVA Industrial Solutions Inc. excels in rotating equipment vibration analysis in Regina. Our experienced technicians employ advanced sensors and analysis techniques to monitor and diagnose your machinery’s condition. We deliver comprehensive data on vibration spectra, enabling you to address issues swiftly. Our services ensure the reliability and longevity of your equipment. With our detailed reports, you can make well-informed maintenance decisions. We serve various industries, including power, oil, and gas, providing top-tier vibration analysis solutions. Our team keeps abreast of the latest technologies and methodologies. We conduct thorough assessments to uncover the root causes of vibration problems. Opt for our expert rotating equipment vibration analysis in Regina, SK, to ensure optimal performance and safety. We also train your staff to identify and address potential vibration issues, enhancing your in-house capabilities.

Our Other Services

LASER ALIGNMENT Regina

Precision shaft alignment provides several advantages: reduced energy consumption, balanced vibration levels, and minimized wear on bearings, couplings, and mechanical seals, which extends equipment lifespan.

MODAL ANALYSIS AND OPERATING DEFLECTION SHAPE Regina

Diagnosing rotating machinery often requires structural vibration analysis, typically performed through Operating Deflection Shape (ODS) Analysis or Modal Analysis.

PREDICTIVE MAINTENANCE (PDM) SERVICES Regina

DVA’s Predictive Maintenance Programs and Services are essential for maintaining a healthy and reliable equipment operating environment. Our services enhance reliability, improve safety, optimize asset lifespan, and boost production and operational efficiencies.

INDIVIDUAL TRAINING PROGRAMS Regina

Our experts at DVA provide comprehensive, hands-on training for your team on the instruments you use and any reliability or maintenance programs you wish to implement.

FAQ - Vibration Analysis

What does Vibration Analysis entail in Saskatchewan?

In Saskatchewan, vibration analysis involves using sensors and monitoring technologies to evaluate the vibrations from industrial machinery and equipment. This approach provides precise measurement and analysis of vibration data, helping detect faults like imbalances, misalignments, and wear early. Identifying these issues promptly prevents costly repairs and operational downtime.

Why is minimizing vibrations crucial for rotating machinery?

Keeping vibration levels low in rotating machinery is vital for operational efficiency and preventing premature wear and potential breakdowns. Dynamic Field Balancing adjusts rotating parts to reduce vibrations, improving machinery performance and longevity.

How does Calibration influence Dynamic Field Balancing?

Calibration ensures the sensors and measurement devices used in Dynamic Field Balancing are accurate and reliable. Precise calibration guarantees the data collected during balancing is accurate, enhancing fault detection and correction capabilities.